More supply chain transparency: Together for Sustainability

The Together for Sustainability (TfS) initiative, founded in 2011 by companies in the chemical industry, aims to systematically assess and improve sustainability sourcing practices across the globe, including ecological and social aspects. Suppliers are scored either on the basis of self-reported information, original documents, and publicly accessible information (CR assessments), or on information obtained during audits (CR audits). The evaluation results are utilized by TfS member companies, who abide by all restrictions stipulated within competition law. We thus have access not only to the evaluations of suppliers selected because of their risk rating, but also to assessments and audit results for other vendors who provide us goods and services.

To date, TfS has enabled us access to evaluations for more than 300 of our most important suppliers. At our prompting, around 100 of these assessments were initiated in 2015, focusing first on raw material and packaging vendors. In addition, we also conducted TfS audits on nine vendors in 2015. For 2016, we have scheduled TfS audits with more than 15 other suppliers.

For around 50 of our suppliers, the CR assessment has yielded significantly below-average results. A root cause analysis showed that most of these vendors had not provided original documents, which in turn negatively impacted the results. We will therefore contact these suppliers once more in 2016 in order to obtain a realistic assessment.

Stringently monitoring working conditions in mica mines

Among other materials, we utilize mica from northern India in the manufacture of our effect pigments. Child labor is extremely common in this region, which is plagued by poverty and political uncertainty. We source mica exclusively from licensed mines. This formal working environment is the only way to ensure that the mines and processing plants are complying with social standards. For mica collected outside of formal working conditions, we cannot rule out the use of child labor, nor can we monitor compliance with fundamental labor standards.

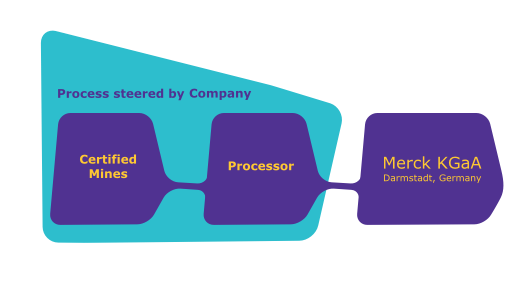

Our supply chain is structured to allow us influence over our vendors, and we have furthermore implemented a series of oversight mechanisms. In doing so, we can ensure that our suppliers adhere to the principles of our Human Rights Charter as well as the requirements of the Merck KGaA, Darmstadt, Germany Responsible Sourcing Principles.

We cultivate direct business relationships with the mica mine operators and mica processing plants. We have an office in the region, and our staff there are in close contact with our business partners, who have in turn been instructed on our values, as well as the social and environmental standards we expect of our suppliers. In addition to these measures, we have also installed a tracking system to monitor the origin of our mica.

We use a monitoring and audit system to track compliance with our social and environmental standards. The IGEP Foundation (Indo-German Environment Partnership), a local organization, arranges unannounced visits every month to check the labor conditions in the mines, including occupational safety and adherence to the ban on child labor. In addition to this, Environmental Resource Management (ERM), an international consultancy, conducts annual audits of all the mines and processing plants, investigating both working conditions as well as environment, health and safety issues. At the beginning of 2016, ERM audited six of our mica suppliers. Roughly 90% of the corrective actions specified in either these audits or the preceding ones had already been implemented or were being implemented at the time of the audit. The red flags identified primarily pertained to occupational safety measures and gaps in the implementation of management systems. Our employees in India pay regular visits to the mines and processing plants to check whether these corrective actions are still being carried out.

In partnership with IGEP, we are also working to improve the living conditions of the families in Jharkhand, a region in northeastern India where we source mica. To this end, we are financing three schools with an affiliated daycare center, as well as two vocational training centers for tailoring and carpentry. More than 500 children and adolescents are enrolled in these institutions. At a fourth school opened by one of our mica suppliers in 2014, we furthermore provide scholarships for 100 children.

We are improving medical care in the region through a local health center that is operated by the IGEP Foundation. This facility has a doctor and a nurse on duty every day and helps increase access to healthcare for the region's 20,000 residents. The doctor and nurses also pay visits to schools and villages in the vicinity.

Mica supply chain