Interview With Johannes Canisius

Johannes Canisius, who holds a PhD in Chemistry, is one of the minds behind our latest vision for liquid crystal technology. Since 2012, the 49-year old Merck KGaA, Darmstadt, Germany employee has been working with his team on the development of liquid crystal windows (LCWs). Head of the LCW business field within our Performance Materials business sector, Canisius explains the benefits of this innovative application.

Interview

You and your team have developed a new way to shade windows from the sun. What inspired you?

When the sun shines into an office, the bright light warms up the room and makes it hard to see – so you put down the blinds. But the problem is that these darken the room, meaning you then have to turn on a light. And people often use air conditioning to cool the room down. We asked ourselves whether there might not be a better, more sustainable solution. We have essentially put sunglasses on the windows. Our liquid crystal technology allows the level of incoming light to be adjusted at the touch of a button. If the sun is shining, the room can be immediately darkened, which means it is less prone to heating up. This technology reduces the amount of energy consumed by air conditioning and lighting. Blinds can be done away with altogether, boosting the general feel good factor – with an uninterrupted view of the great outdoors, people become more creative and productive!

Seems like a brilliant idea – how did it come about?

Our company is the world market leader in liquid crystal technology. For a long time, we focused our efforts on reducing the energy consumed by the liquid crystal displays of smartphones, tablets and TVs. But then in 2012 we realized that we could use our liquid crystals for so much more. We heard about the Dutch start-up Peer+, a small team that was experimenting with liquid crystals in windows. We partnered with them for two years before acquiring the company. With our ideas and expertise, we complement each other perfectly.

What role does sustainability play in your work?

Fortunately, it plays a major role. Every day, I have the chance to work on new, sustainable ideas. In developing our liquid crystal window technology, we received a lot of support from the Executive Board, even during challenging stages. The drive to blaze new trails requires top-down buy-in, which we definitely have at our company!

Saving energy

Our liquid crystal windows can help save energy. Since they absorb a portion of the sunlight and therefore the heat, the room does not grow as warm, reducing the need to use air conditioning. Light still enters the building, just not so bright that it's blinding. People no longer need to draw the curtains or drop the blinds, nor do they need to turn on the lights. All in all, liquid crystal windows can thus save up to 40% of the energy that would normally be used for air conditioning or lighting.

Up to

40 %Buildings outfitted with liquid crystal windows consume up to 40% less energy otherwise required for air conditioning or lighting.

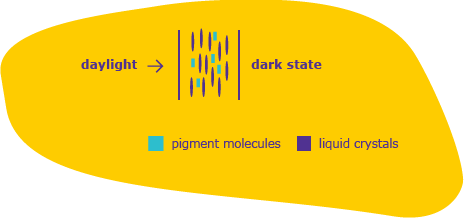

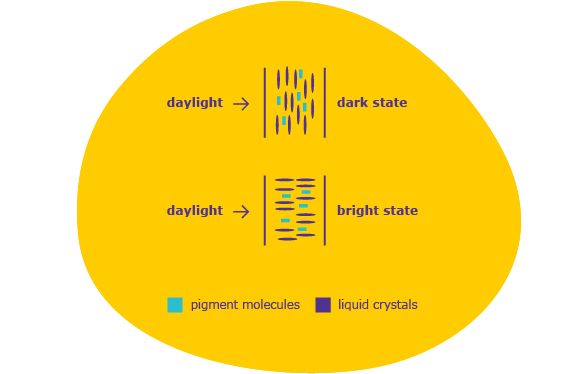

Liquid crystal windows as a sunshade – how it works

A mixture of liquid crystals and pigment molecules is placed between two panes of glass. The alignment of these crystals changes when an electrical current is applied. When users push the button to alter the current, the liquid crystals arrange the pigment molecules so that they absorb more or less light, depending on their positioning. This controls how much light the window transmits. If it’s set to “bright”, light penetrates the window. If darkened, light and heat are absorbed – but it’s still possible to see out.

Producing their own electricity

Liquid crystal windows could be made to generate their own electricity. The liquid crystal mixture can be designed so that it functions as an optical waveguide. Incoming light would be conducted to the inner frame of the window, which contains small solar cells. These would then produce enough electricity to enable the windows to operate.

Conserving resources

Buildings with giant window façades have one major problem: it takes a lot of time, effort and money to block the sun. Electric blinds require repairs - and it is expensive as well as time-consuming to install a new motor. As a result, large office buildings often have all the motors changed at once, even the ones that still work, thereby wasting a lot of materials. With our liquid crystal windows, however, blinds are no longer needed. These windows require practically no maintenance and are 100% recyclable.

Our liquid crystal windows are 100% recyclable after the end of their useful life.

“Our people have creative ideas and develop innovative and sustainable solutions with the full backing of our company. Johannes Canisius' team is a quintessential example: Their liquid crystal windows have taken our liquid crystal technology in a completely new direction and will soon be an integral component of state-of-the-art architecture and sustainable building management.”Walter GalinatExecutive Board member and CEO Performance Materials

“Our people have creative ideas and develop innovative and sustainable solutions with the full backing of our company. Johannes Canisius' team is a quintessential example: Their liquid crystal windows have taken our liquid crystal technology in a completely new direction and will soon be an integral component of state-of-the-art architecture and sustainable building management.”Walter GalinatExecutive Board member and CEO Performance Materials

Cool to the touch

At our global headquarters in Darmstadt, we have already installed our liquid crystal windows in our modular Innovation Center as well as our OLED materials production building. “During the summer, you can immediately feel the room cool down when the windows are darkened and the sunlight is blocked out,” says Johannes Canisius, reporting on the successful test phase.

The feel-good factor

Displays? No problem! But windows? With our new technology, we were faced with the major challenge of breaking into the market of the construction industry, a sector that is relatively conservative when it comes to innovations. However, modern architecture is increasingly catering to the feel-good factor, which played right to our strengths. Over the last several years, the percentage of glass used in both private homes and large office complexes has increased exponentially. This is the perfect time for our liquid crystal windows.

“Modern buildings are becoming more and more like living organisms, where the façade works like our skin in keeping the interior comfortable. Like in a human body, all parts of a building must function in harmony. Our liquid crystal windows fit the bill perfectly because they can be seamlessly integrated with other lighting and climate controls in a building, optimally making use of available daylight and all working together to make the building a pleasant place to be.”Caspar van OostenCEO Merck Window Technologies, Eindhoven, Netherlands a subsidiary of Merck KGaA, Darmstadt, Germany, co-developer of the LCW technology, founder and joint owner of the start-up Peer+

“Modern buildings are becoming more and more like living organisms, where the façade works like our skin in keeping the interior comfortable. Like in a human body, all parts of a building must function in harmony. Our liquid crystal windows fit the bill perfectly because they can be seamlessly integrated with other lighting and climate controls in a building, optimally making use of available daylight and all working together to make the building a pleasant place to be.”Caspar van OostenCEO Merck Window Technologies, Eindhoven, Netherlands a subsidiary of Merck KGaA, Darmstadt, Germany, co-developer of the LCW technology, founder and joint owner of the start-up Peer+

Commercializing liquid crystal windows

Our windows are on the verge of market launch, and our first production facility in Veldhoven (Netherlands) is scheduled for completion some time in 2017. Our initial target group will be the premium architecture segment, where large window façades envelop high rises and corporate headquarters, and the task of regulating the incident sunlight is complicated and expensive. Once these windows have established a firm foothold in this sector, we will turn our attention to the mass market. We believe that liquid crystal windows will soon become the window of choice.

It took 40 people – among them engineers, scientists, and quality managers – five years to develop our liquid crystal windows, from the initial idea in 2012 to market maturity in 2017.