We procure the raw materials, packaging materials, technical products, components, and services we need from over 60,000 suppliers across more than 130 countries. All goods and services purchased in 2013 totaled € 4.1 billion, with € 4.3 billion in 2014.

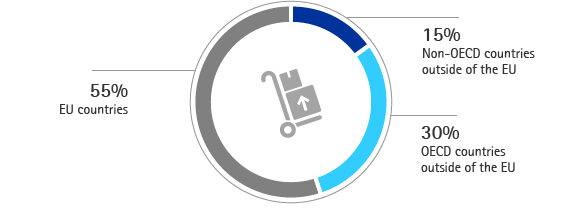

Of the goods and services (including R&D services) purchased in 2014, we purchased 55% from suppliers based in EU countries and 30% from vendors in OECD countries outside the EU. The share of goods and services sourced from non-OECD countries outside the EU rose from 12% in 2012 to 15% in 2014.

2014 Procurement volume (%)

These figures make it clear that emerging economies are playing an increasingly important role in the company's sourcing activities. One major reason is that certain pharmaceutical products are being produced in the developing and emerging countries in which they are commercialized. For instance, the medicines we manufacture in India, Pakistan and Indonesia are intended for those markets. This approach reflects our Access to Health strategy and is also stipulated by local law. For our products to be manufactured locally, we require compliance with our quality and safety standards; the same goes for the transfer of our technology, skills and intellectual property. All of Merck KGaA, Darmstadt, Germany's pharmaceutical products, whether for developed or developing markets, are produced in manufacturing plants that meet global Good Manufacturing Practices (GMPs).

Merck KGaA, Darmstadt, Germany has no internal guidelines stipulating that local suppliers are to be given preference in the contract award process. However, there are cases in which local vendors have a competitive advantage owing to their proximity, for instance when it comes to the purchase of technology or packaging materials. Furthermore, local legislation sometimes requires us to use local vendors, especially in the pharmaceutical industry. Otherwise, we source our goods and services globally, depending on availability and supply.

Responsibility in the mica supply chain

Merck KGaA, Darmstadt, Germany utilizes mica from India as a primary raw material for effect pigment production. This special mica has properties that are necessary for the manufacture of top-quality pigments. In the course of an investigation in 2008, we discovered that at the start of the supply chain, mica is sometimes collected by children, generally together with their parents. This is not compatible with our corporate values, nor with the principles of our Human Rights Charter .

We take a firm stance against child labor. As a signatory to the United Nations Global Compact , we are actively fighting to end this practice. We require our suppliers to act accordingly and contractually prohibit them from utilizing child labor.

As a result of our 2008 supply chain audit, we have realigned the mica supply chain in order to prevent child labor and to ensure that vendors comply with the principles of our Human Rights Charter. Since then, we have been sourcing only mined mica. We no longer use any mica that is collected because, in this informal work environment, we cannot guarantee that child labor is not being used. However, we consider it important to maintain our business relationships with suppliers in the regions where mica comes from and thus safeguard jobs in Jharkhand, a region in northeast India plagued by poverty and political uncertainty. This is why we maintain direct business relationships with our partners along the mica supply chain, meaning the mica mine operators and the mica processing plants. We have set up an office in the region; our staff there are in close contact with our business partners, whom we have instructed on our values, along with the social and environmental standards that we expect of them. Mine owners and processing plants accept their responsibilities and help us keep the mica supply chain free of child labor.

In addition to these measures, we have also set up a mica tracking system in order to guarantee that the raw materials supplied to Merck KGaA, Darmstadt, Germany come exclusively from mines and not from uncontrolled sources. In order to track the mica flow, owners maintain a daily log of the amount produced by their mines. It is unlikely that mine owners would falsely reported inflated production figures for the individual mines and then make up the difference with mica from uncontrolled sources. After all, such a course of action would incur additional licensing fees that would then have to be paid to the government. We crosscheck the final amounts once a month.

On top of this tracking system, we have also developed an audit system that entails surprise audits conducted by us or third party partners. This system aims to ensure that the mines and processing plants are complying with our requirements for environmental protection, safety, and working standards. Once a month, a local organization investigates the working conditions and standards in the mines. In addition to this, an international organization also conducts an annual audit that reviews both working standards, as well as environmental, health and safety standards. The audit reports indicate all issues identified and specify corrective action. Our employees in Jharkhand check whether the required corrective action has been taken.

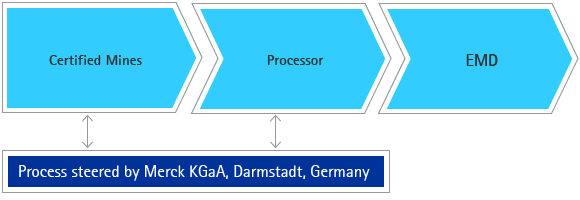

Mica supply chain

In 2013 and 2014, we conducted 14 audits on our mica suppliers that were part of the standard yearly audit process. Around three-fourths of the corrective actions specified in the previous audits had already been taken or were underway when the audit was performed. Because they failed to carry out the corrective actions in a satisfactory manner, we terminated business relations with two of our vendors.

Social engagement along the mica supply chain

Apart from our strategy to guarantee oversight of the entire mica supply chain, we are working together with the IGEP Foundation to better the living conditions of the families in the mica mining regions of India. We are therefore financing three schools with daycare centers as well as a vocational training center for tailoring and carpentry. These schools now have an enrollment of around 500 children. At a fourth school opened by one of our mica suppliers in 2014, we furthermore provide scholarships for 100 children.

We are improving medical care in the region through a local wellness center that is operated by the IGEP Foundation. This facility has a doctor and a nurse on duty every day and is highly appreciated by the region's 20,000 inhabitants, who previously had no health care at their disposal. The doctor and nurses also pay visits to schools and villages in the vicinity.

From 2010 until 2013, we partnered with the Indian non-profit organization Bachpan Bachao Andolan to develop 20 "child-friendly villages" in Jharkhand. This three-year project aimed to improve understanding for children's rights and foster the basic conditions for children to regularly attend school. In collaboration with local communities, civil servants, and teachers, the project has made visible progress.

Stakeholder dialogue on the mica supply chain

Since the start of our supply chain changeover, we have been keeping interested customers and other stakeholders regularly informed on the progress made on mica sourcing as well as the associated projects. Employees in our Jharkhand office are in communication with our project partners and other stakeholders, such as local and federal agencies.