Our basic expectations for suppliers and service partners include their compliance with fundamental environmental and social standards. Therefore, we have further developed our procurement strategies in order for our supply chain worldwide to adhere more closely to environmental, compliance and social standards and to prevent violations.

Supplier Management

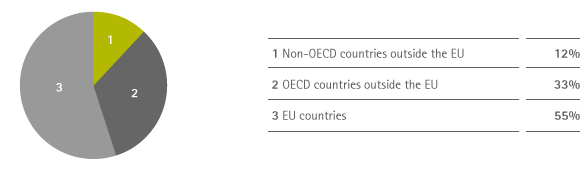

For our business activities we need raw materials, packaging materials, technical products, components and services; in 2012, we purchased all these commodities from more than 50,000 suppliers in over 100 countries worldwide. Of the goods and services (including R&D services) procured in 2012, totaling approximately € 4 billion, we purchased 55% from suppliers based in EU countries and 33% from suppliers in OECD countries outside the EU. Around 12% came from suppliers in non-OECD countries outside the EU.

Procurement volume 2012 in %

Our basic expectations for suppliers and service partners include their compliance with fundamental environmental and social standards derived primarily from the ILO Core Labor Standards and the UN Global Compact. Therefore, since 2009, we have been supporting the Compliance Initiative of the German Federal Association for Materials Management, Purchasing and Logistics (BME) and have additionally signed the BME Code of Conduct . This contains basic rules for combating corruption, violations of antitrust law, child labor, and minimum requirements for environmental protection in the supply chain.

Info box: BME Code of Conduct

The BME Code of Conduct contains international cross-industry minimum standards for combating corruption, collusion in violation of anti-trust law, child labor, and forced labor, as well as for promoting ethical principles toward suppliers. It also encompasses principles for upholding human rights, for protecting health and the environment, and for fair working conditions.

In the last two years, we have refined our procurement strategies in order for our supply chain worldwide to adhere more closely to environmental, compliance and social standards, and to prevent violations. We have put into effect a new procurement guideline and published new standard operating procedures for the supplier management and purchasing process of Merck KGaA, Darmstadt, Germany. The aim is to anchor CR aspects more firmly in procurement activities in order to take them better into account in the selection, assessment and management of suppliers.

We have developed our Responsible Sourcing Principles , which include not only environmental, social and compliance aspects, but also the requirements that we expect, for example, when commissioning animal studies. Our Responsible Sourcing Principles consolidate the requirements we place on our suppliers concerning responsible conduct. In addition, with these principles we also clearly highlight the responsibility of suppliers to apply our Corporate Responsibility Standards also to their upstream value chain.

In the course of 2013, we intend to integrate our Germany Responsible Sourcing Principles into the respective general terms and conditions worldwide. In this way, we are underscoring the principles we have already defined in our Code of Conduct and Social Charter by providing our suppliers with a uniform document.

Core features of our sustainable CR supplier management approach are:

- General terms and conditions: In our general terms and conditions, we are globally integrating the commitment to comply with the principles of our Code of Conduct and Social Charter. By the end of the first quarter of 2013, almost all legal entities had adapted their respective general terms and conditions. In the course of 2013, a reference to our Responsible Sourcing Principles will be added successively to the general terms and conditions.

- Supplier self-disclosure: With their self-disclosure, our suppliers provide information on their compliance with our Code of Conduct and Social Charter, as well as available (ISO) certificates. In the 2011-2012 period, we expanded the self-disclosure process started in 2010 that our suppliers have to undergo. It has now been established in Germany, Brazil, Mexico, Switzerland, Japan, and India. By the end of 2013, this will also be the case in France, the United States, China, Italy, the United Kingdom and Ireland. In these countries, we request higher-risk suppliers from whom we procure more than a defined purchasing volume to provide a self-disclosure. The global implementation process for self-disclosures has been initiated and is being successively executed with the introduction of our new computerized supplier management system.

- Sustainability audits: In order to monitor compliance with our Code of Conduct and Social Charter, depending on the risk potential we conduct sustainability audits at selected suppliers. A Group-wide operating procedure was created in 2012 for executing and following up audits. We select suppliers for an audit by dividing our supplier portfolio into risk groups based on the criteria country risk, product category and the sales that the supplier generates from its business with us. Suppliers in an OECD member state, for example, are classified into a lower risk group. In addition, suppliers are also audited if there are indications of a lack of compliance with our requirements. Audit observations may be classified as “critical defects”, “major defects” or “minor defects”. The audit results and any necessary corrective actions are communicated to the supplier. If observations are classified as critical or major, we monitor the implementation of the defined corrective actions and also initiate supplier requalification or disqualification where necessary. The audit team additionally determines the interval at which follow-up audits are to be conducted.

We conducted 36 audits in 2011 and 2012 according to the newly developed system. None of them resulted in critical defects. However, 18 audits revealed major defects, which we are tracking and monitoring. Therefore, we demanded a Corrective Action Plan (CAPA) from the suppliers concerned, which describes the measures to address the defects. This will be monitored by auditors. In addition, we will re-audit these suppliers as from 2014. Based on our risk potential analysis, we plan around 30 audits per year at suppliers with a high risk potential. These take place mainly in non-OECD countries.

Info box: Evaluation of audit results and follow-up

Critical: Any observation rated as Critical must be rectified or mitigated as soon as possible. Proposal for corrective actions shall be submitted by the supplier to Merck KGaA, Darmstadt, Germany within one week after receiving the audit report

Major: Any observation rated as Major is believed to be significant enough to require a formal corrective action response by the supplier within one month of the receipt of the audit report

Minor: Any observation rated as Minor does not require a formal corrective action plan and the implementation of associated corrective actions will also not

Our Group function Procurement is responsible for all activities and measures that further incorporate corporate responsibility aspects into our procurement processes and supplier management process. Since 2011, Procurement has appointed a CR officer who handles purchasing activities relating to the topic of corporate responsibility and coordinates the implementation of the various sub-projects. A special intranet page informs the staff of Procurement in all countries about the guidelines and measures we apply to ensure compliance with our supply chain standards.

Responsibility in the mica supply chain

Mica is a raw material we use for one of our pigment product groups. When examining the mica supply chain, we discovered in 2008 that at the start of the supply chain mica is partly also collected by children, generally together with their parents. This is not compatible with our corporate values and the principles of our Social Charter. Consequently, we have realigned the mica supply chain in order to prevent child labor and to ensure that the principles of our Social Charter are complied with.

It was important to us to maintain our business relationships with suppliers in the regions where mica comes from and thus safeguard jobs in Jharkhand, a region in northeast India plagued by poverty and political uncertainty. Today we procure mica exclusively from mining and not from collecting. Based on information provided by our suppliers, we have introduced a system for tracking the origin of the raw material. It is regularly checked by staff from the office we recently set up in the region. We maintain regular and close contact with our business partners in Jharkhand and have informed them in detail about our values and our expectations regarding the social and environmental standards to be complied with. In addition, we conduct and commission audits at our suppliers and further processing partners. We also check that they adhere to our requirements regarding environmental protection, safety, working standards and compliance. If we observe any deviations we document them in an audit report and define corrective actions, monitoring the implementation of such corrective actions.

In addition to changing our mica procurement process, we are working to improve education and health care programs in the regions where the raw material comes from. For this purpose, we are financing three schools with an affiliated daycare center, which are now regularly attended by around 380 children, as well as a training center for tailoring and carpentry. We are improving medical care by means of a local health center. A doctor and a nurse are on daily duty, regularly visiting the surrounding villages and our schools. In addition, we support an Indian non-governmental organization with a project for developing “children-friendly villages”. This aims to improve the understanding of children's rights and the general conditions for children to regularly attend school.

In the course of changing our supply chain, we regularly informed interested customers and other stakeholders on the progress made in mica procurement and the accompanying projects.

| XLS Download |

|

Goals: Supplier management | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Strategic goal |

Action |

By? |

Status in 2011 and 2012 |

Status |

|

Sustainability in the supply chain |

Introduce the new supplier management process within the most important legal entities |

End of 2012 |

A new supplier management process has been instituted in the most important legal entities. |

|

|

|

Adapt the general terms and conditions to integrate our Responsible Sourcing Principles into all orders |

End of 2013 |

|

|

|

|

Conduct CR audits on 30 suppliers with a risk potential |

End of 2013 |

|

|

|

|

Create the technical prerequisites for obtaining supplier self-disclosures in France, the United States, China, Italy, the United Kingdom, and Ireland by implementing a new computerized supplier management system |

End of 2013 |

|

|

|

|

Collect supplier self-disclosures from higher-risk suppliers from whom we procure a volume above a defined threshold, in the countries Germany, Brazil, Mexico, Switzerland, Japan, India, France, the United States, China, Italy, the United Kingdom, and Ireland |

End of 2013 |

|

|

|

Legend: | ||||